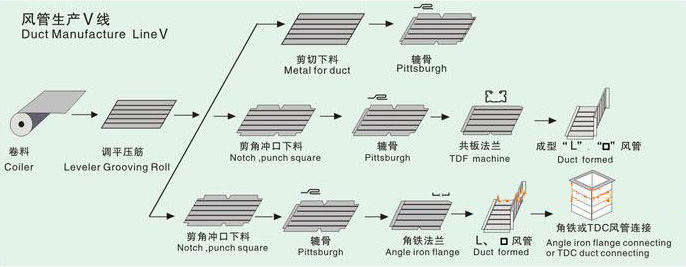

Working flow of square duct machine - auto duct line III:

Buildup of square duct machine - auto duct line III:

-- Two power metal feeding frames

-- One leveling & grooving roller machine

-- Four hydraulic notch and die

-- Hydraulic shearer and folding machine

-- Industrial PLC control and specific software

Main technical data of square duct machine - auto duct line III:

|

Item |

Data |

|

Max. plate width for square ducts |

1300mm |

|

Suitable plate thickness |

0.4-1.2mm |

|

Tolerance in duct length |

+/-0.5mm |

|

Tolerance in duct diagonal |

+/-0.8mm |

|

Max. plate feeding speed |

10m/min |

|

Line working capacity |

1000m2 square ducts per shift |

|

Line dimension |

About 5600 x 2100 x 1500mm |

|

Line weight |

About 4500kg |

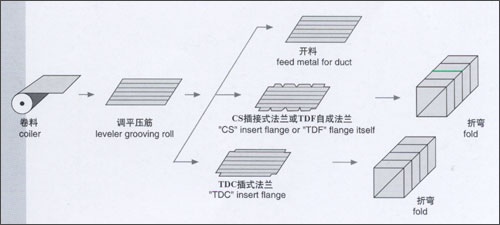

III Square duct machine - auto duct line V

This line consists of electric driven decoilers, leveling and grooving device, hydraulic notching and punching device, shearer, movable Pittsburgh lock machine, duplex trans-verse duct flange machine, TDF folder and PLC control system. The line is efficient with high performance, less space and wide capability.

Working flow of square duct machine - auto duct line V:

Buildup of square duct machine - auto duct line V:

-- Electric decoiler: two

-- Leveling & grooving device: one set

-- Hydraulic notching machine and dies: four

-- Hydraulic shearer: one

-- Duplex Pittsburgh lockformer: one

-- Duplex TDF flange making machine: one

-- Mechanical Feeding System and Hydraulic Folding system: one

--Transmission table: 2

-- Control System and software (English version): one set

I Square duct machine - auto duct line II:

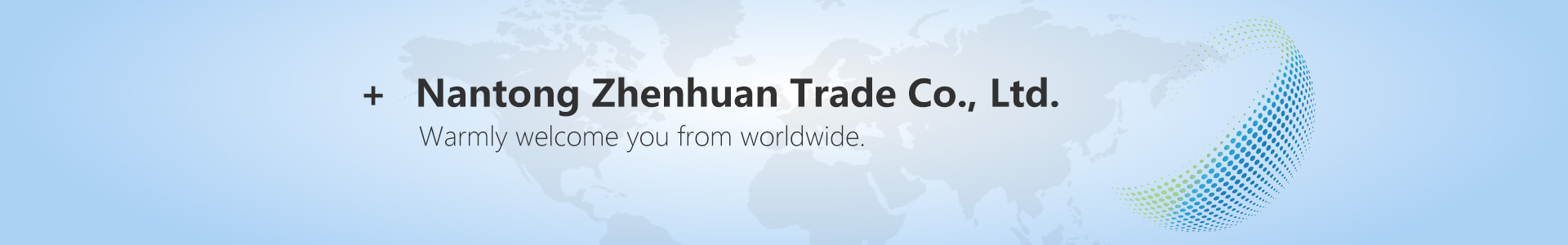

Working flow of square duct machine - auto duct line II:

Buildup of square duct machine - auto duct line II:

--Two electric decoilers

--One leveling & grooving device

-- Hydraulic notching device and dies, four

-- Hydraulic shearing machine

-- Industrial computer and special software