HVAC Duct Machines

Wire Bending Machines

Bra Making Machines

Tube/Pipe Machines

Tank Machines

Metal Processing Machines

Motor Making Machines

Welding Machines

Battery Machines

Metal Spinning & Flanging Mach

Textile Machine

Packing & Wrapping Machines

Heat Exchange Machines

Other Machinery

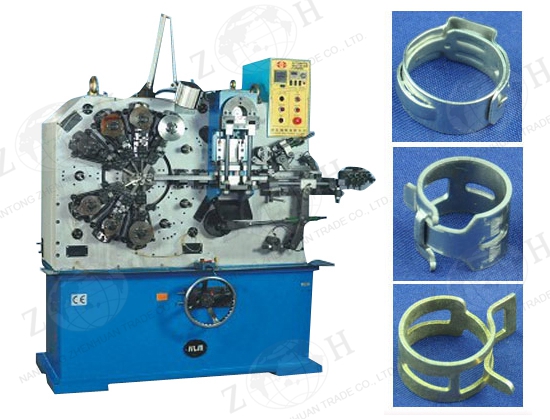

Hose Clamp Machine

Description of hose clamp machine:

Hose clamp machine is our state-of-the-art design for automatically producing wire/plate products in complex shapes, not only various hose clamps.

The machine combines leveling, punching, bending and forming together, much higher efficient than conventional press forming.

Bending slides can be designed to be 360° adjustable (optional).

Typical hose clamps can be produced:

II Main advantages comparing with conventional press forming:

2.1 Saving material: conventional pressing machine needs wider strips for automatic production; This machine uses exact wide strip for production.

2.2 High efficiency: capability of one automatic machine is equal to that of seven pressing machines at least. And so energy consumption is also saved.

2.3 More stable processing quality because of continuous processing automatically.

2.4 Cheaper mould cost: one combined mould can replace several moulds on several pressing machines; Mould frames are also saved.

2.5 Automatic lubricating, less wearing, suitable for mass production.

III Main technical data of hose clamp machine

|

Item |

Data |

|

Machine code |

ZHLJ-26 |

|

Suitable carbon steel wire gauge |

Φ0.6~2.5mm (3mm) |

|

Suitable steel strip width |

30mm |

|

Suitable steel strip thickness |

0.3~1.2mm |

|

Max. feeding length per stroke |

200mm (250mm) |

|

Feeding precision |

+/-0.005mm |

|

Punching force of punching head |

10 ton |

|

Total motor power |

3.7kW |

|

Production speed |

200 pcs/min |

|

Machine dimension |

About 1900 x 990 x 1900mm |

|

Machine weight |

About 2100kg |

|

Linear guide |

ABBA from Taiwan |

|

Servo motor and inverter |

TECO from Taiwan |

|

Main bearings |

SKF from Japan |

Product display